In the world of construction, precision and durability are non-negotiable. From framing walls to marking stone, the humble carpenter pencil plays a vital role in ensuring accuracy on the jobsite. But not all pencils are created equal. One key feature that separates a reliable tool from a frustrating one is the carpenter pencil strong core. Whether you’re a seasoned builder or a woodworking enthusiast, understanding why core strength matters can make a noticeable difference in your workflow and results.

The Anatomy of a Carpenter Pencil

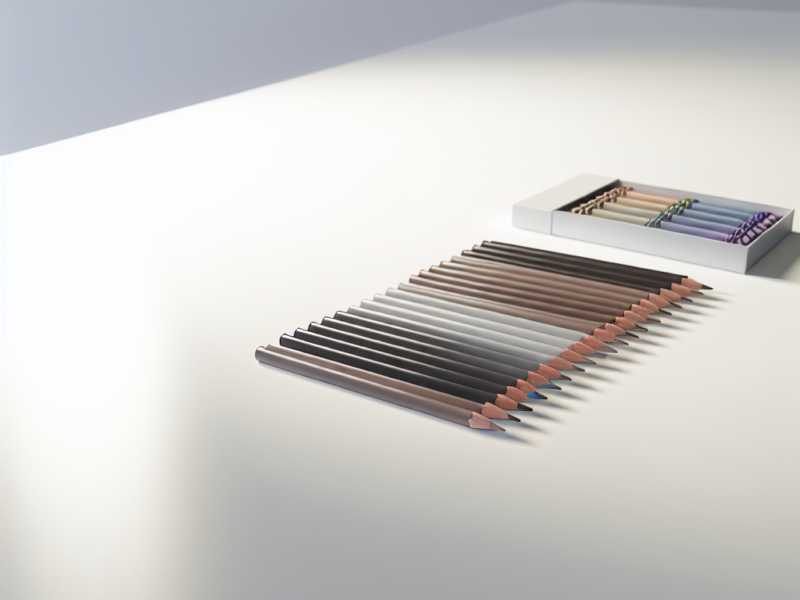

At first glance, a carpenter pencil stands out due to its flat, rectangular body. This design serves a practical purpose: it prevents the pencil from rolling off inclined surfaces like roofs or workbenches. But beneath the surface, the real workhorse is the core — the marking material inside the pencil that determines how it performs under pressure.

Unlike standard round pencils, which typically use a thin graphite core, carpenter pencils feature a much thicker and stronger core. This modification allows them to make visible marks on rough, uneven surfaces such as raw lumber, concrete, and stone without constantly breaking or wearing down.

According to Gray Hill Woodworking LLC, the thick graphite core is specifically engineered to withstand the rigors of construction environments. This resilience ensures that marks remain visible even on coarse materials, reducing the need for constant resharpening and interruptions.

Why Core Strength Matters in Construction

Imagine you’re halfway through measuring and cutting framing studs for a wall. You reach for your pencil to mark a cut, only to find the tip has shattered — again. Not only is this frustrating, but it also slows down your workflow and compromises precision. That’s where a strong core becomes essential.

Here’s why core strength is a game changer in carpentry and construction:

- Durability: Stronger cores resist breakage when marking on hard or uneven surfaces.

- Precision: A robust core maintains its shape longer, allowing for consistent and accurate lines.

- Efficiency: Less time spent sharpening means more time focused on the task at hand.

- Versatility: Strong cores can mark on a variety of surfaces — wood, drywall, concrete, and even metal.

These advantages are especially important in high-paced jobsite environments, where efficiency and accuracy are vital to meeting deadlines and maintaining quality standards.

Core Materials: Graphite vs. Charcoal

Most carpenter pencils use a graphite-based core, but not all graphite is created equal. The hardness and composition of the core can vary significantly. Some manufacturers are now exploring alternative materials like charcoal to enhance performance.

| Core Material | Hardness | Durability | Mark Visibility | Best For |

|---|---|---|---|---|

| Standard Graphite | Medium | Moderate | Good | General woodworking |

| Hard Graphite | High | High | Fair | Rough surfaces, concrete |

| Charcoal | Very High | Very High | Excellent | Precision marking, rugged materials |

As highlighted by DurZerD, charcoal cores offer increased hardness and longevity. These cores are less prone to crumbling under pressure, making them ideal for marking on surfaces like concrete or stone. Additionally, they require fewer sharpenings, which minimizes downtime — a critical factor in professional settings.

Sharpening and Maintenance: A Hidden Cost

Frequent sharpening may seem like a minor inconvenience, but over the course of a project, it adds up. Every time you stop to sharpen a pencil, you lose momentum. A stronger core reduces this need, allowing for longer uninterrupted work sessions. This is particularly valuable in environments where power tools, dust, and time constraints make even small inefficiencies costly.

Moreover, maintaining a consistent tip shape is easier with harder cores. Softer cores tend to wear unevenly, leading to inconsistent line widths and less precise markings. In contrast, a strong core retains its edge, ensuring that every mark is clean and legible.

Specialized Use Cases for Strong-Core Carpenter Pencils

While the average DIYer might not notice the difference between pencil cores, professionals certainly do. Here are a few scenarios where a carpenter pencil strong core proves indispensable:

- Roofing: Sloped surfaces demand a pencil that won’t roll away and a core that can mark on asphalt shingles or metal flashing.

- Concrete Formwork: Marking on cured concrete or rebar requires a core that won’t crumble on impact.

- Framing: Quick, visible marks on rough lumber are essential for accurate cuts and alignment.

- Stonework: When working with tile, granite, or pavers, only a hard core can leave a visible mark without constant breakage.

OEM and Manufacturing Considerations

From a manufacturing standpoint, producing a strong-core carpenter pencil involves careful material selection and engineering. The core must be balanced in terms of hardness and visibility — too hard and it may scratch without marking; too soft and it breaks easily. This balance is achieved through precise formulation during the extrusion and drying stages of core production.

OEM suppliers also consider the casing material. The wooden housing must be dense enough to support the core without splintering during sharpening. Basswood and linden are popular choices due to their strength and ease of machining. For custom pencils, manufacturers may even offer hybrid cores or coatings to enhance mark visibility on specific materials.

Pros and Cons of Strong-Core Carpenter Pencils

| Pros | Cons |

|---|---|

| Highly durable for rough surfaces | Can be harder to erase |

| Requires less frequent sharpening | May cost more than standard pencils |

| Improves marking precision | Limited availability in some regions |

| Performs well on non-wood surfaces | May feel too hard for softwood applications |

These trade-offs are usually minimal in professional contexts, where performance and reliability outweigh small cost differences. However, understanding them can help buyers choose the right tool for their specific needs.

Final Thoughts: The Core of the Matter

Behind every clean cut and precise measurement on a jobsite is a tool that made it possible — often, a carpenter pencil. But not just any pencil will do. A carpenter pencil strong core is more than a convenience; it’s a necessity for professionals who rely on accuracy, durability, and efficiency.

Whether you’re marking framing studs, scoring concrete, or sketching layout lines on drywall, the strength of your pencil’s core directly impacts your workflow. By choosing the right core material — whether traditional graphite or advanced charcoal — you ensure that your tools are as tough and reliable as the work you do.

For further reading on materials and design, check out the in-depth analysis from DurZerD or explore the functional design insights from Gray Hill Woodworking LLC.

In the end, it’s not just about marking a line — it’s about marking it right, every time.

Related Reading

- Cheap Pencils Break Easily for These Key Reasons

- Pencil Barrel Strength QC Testing Explained

- How Barrel Size Accuracy Impacts Pencil Performance

- Inside a Carpenter Pencil Factory: Flat Pencils OEM Guide

- Graphite Extrusion Process and Core Mixing Explained

- How Graphite Density Impacts Pencil Performance

- Pencil Production Line Explanation and Step-by-Step Process