In the world of OEM pencil manufacturing, brand consistency is not just a marketing buzzword—it’s a non-negotiable pillar of long-term success. Whether you’re a stationery startup or an established global brand, maintaining a cohesive brand identity across every pencil, packaging, and promotional material is essential to build trust and recognition. As competition intensifies and consumer expectations rise, ensuring brand consistency OEM becomes a strategic imperative, not just a design preference.

Why Brand Consistency Matters in OEM Pencil Manufacturing

At its core, brand consistency refers to the uniform application of a brand’s values, visual elements, messaging, and tone across all customer touchpoints. In OEM partnerships, where manufacturing is outsourced but branding remains proprietary, the risk of inconsistency increases. A minor deviation in color, logo placement, or material finish can erode brand perception and compromise customer trust.

According to a Forbes article, consistent branding fosters consumer trust and significantly enhances loyalty. In the context of pencils, this could mean everything from the exact shade of a ferrule to the tactile feel of lacquered wood. For brands operating in the OEM space, this level of detail must be tightly controlled through clear communication and rigorous quality checks.

Challenges of Maintaining Brand Consistency in OEM Models

OEM manufacturing offers cost efficiency and scalability, but it also introduces layers of complexity in brand control. Here are some of the most common challenges:

- Multiple Production Facilities: When pencils are manufactured in different factories or countries, uniformity in materials, finishes, and printing techniques can vary.

- Communication Gaps: Misinterpretation of brand guidelines by overseas teams or subcontractors can lead to inconsistent outputs.

- Supply Chain Variability: Changing suppliers for wood, graphite, or coatings can affect the final product’s appearance and performance.

- Rapid Scaling: As businesses grow quickly, brand dilution becomes a real risk without centralized brand management systems.

These challenges highlight the need for a structured approach to brand governance, especially when working with third-party manufacturers.

Strategies to Ensure Brand Consistency in OEM Pencil Production

To mitigate risks and maintain a unified brand image, OEM pencil brands must adopt a combination of proactive strategies and operational discipline. Below are key approaches:

1. Develop Comprehensive Brand Guidelines

Start with a robust brand manual that includes specifications for:

- Logo usage and placement on the pencil barrel and packaging

- Color codes (Pantone, CMYK, RGB) for paint, ferrules, and erasers

- Typography for any printed text

- Material preferences (e.g., cedar wood, high-polymer graphite)

- Finish types (matte, gloss, semi-gloss)

This document should be shared with every OEM partner and updated regularly. As Siteimprove notes, clear and accessible brand guidelines are essential to harmonize visual and messaging elements across teams and vendors.

2. Standardize Material Inputs

One of the most overlooked aspects of brand consistency is raw material sourcing. Even slight changes in wood grain or ferrule metal can alter the product’s look and feel. Establishing approved suppliers and material specs helps ensure every pencil meets the same standards.

| Component | Standard Specification | Consistency Impact |

|---|---|---|

| Wood Casing | Incense-cedar, FSC certified | Uniform texture, color, and sharpening quality |

| Graphite Core | HB, 60% graphite / 40% clay | Consistent writing experience |

| Ferrule | Aluminum, anodized, gold finish | Color and shine uniformity |

| Eraser | Latex-free, white rubber | Visual match and performance |

3. Implement a Centralized Asset Management System

Using digital tools to store and distribute brand assets—logos, dielines, templates—ensures that every factory or partner accesses the same files. This reduces the chance of outdated or modified versions being used. Platforms like DAM (Digital Asset Management) systems are ideal for this purpose.

4. Conduct Regular Quality Audits

Routine inspections and batch testing are critical in OEM relationships. Brands should schedule periodic factory visits, request pre-production samples, and implement third-party quality assurance checks. This ensures that every production run adheres to brand specifications.

5. Align Internal and External Teams

According to Marcom, internal alignment is just as important as external control. Everyone from the product manager to the packaging designer should be on the same page regarding brand tone, values, and visual elements. Regular training sessions and brand onboarding for new suppliers can reinforce this alignment.

6. Use Prototypes and Golden Samples

Before mass production, develop a “golden sample” that represents the ideal product. This sample should be signed off by all stakeholders and used as a benchmark for future production runs. It acts as a tangible reference for color, finish, and construction quality.

7. Maintain Consistency During Scaling

As your pencil brand grows, new challenges arise—larger order volumes, new markets, more suppliers. The WeAreAmnet blog offers valuable insights into preserving brand identity during rapid expansion. Their key recommendations include:

- Centralizing brand decision-making authority

- Training new partners thoroughly before onboarding

- Using scalable design systems and templates

Growth should never come at the cost of brand dilution. Structured systems allow your brand to scale while preserving its identity.

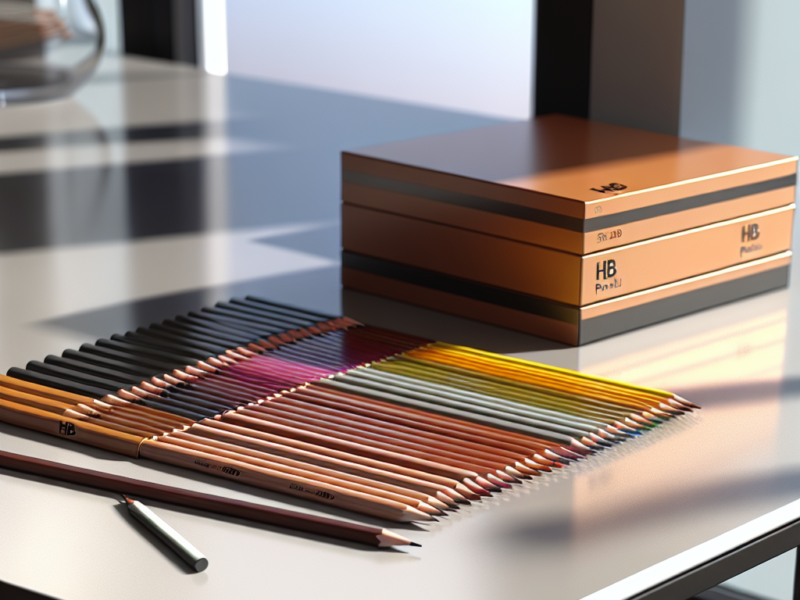

Visual Branding: More Than Just Aesthetics

In pencil manufacturing, visual branding extends beyond the logo. The color of the barrel, the shape of the tip, the sheen of the lacquer—all contribute to brand perception. For example, Blackwing pencils are known for their iconic square ferrule and matte black finish. These design elements are as recognizable as the brand name itself.

Investing in professional design and consistent execution helps elevate your brand above commodity status. As AlphaGraphics emphasizes, these visual cues enhance professionalism and customer trust, reinforcing the brand promise with every use.

Case Study: OEM Brand Consistency in Practice

Consider a mid-size stationery company that outsources pencil production to two factories—one in Vietnam and one in Mexico. Without a centralized asset system, each factory used slightly different logo files and paint suppliers. The result? Retailers received pencils with inconsistent barrel colors and misaligned branding, leading to customer complaints and product returns.

After implementing a unified brand guideline, switching to a single DAM platform, and assigning a dedicated brand manager, the company restored consistency across its product line. Customer satisfaction improved, and the brand regained shelf credibility.

Benefits of Consistent Branding in OEM

When executed correctly, brand consistency in OEM manufacturing delivers tangible business benefits:

- Stronger Brand Recognition: Uniform design increases visibility and recall.

- Customer Trust: Predictable quality fosters confidence and loyalty.

- Operational Efficiency: Clear guidelines reduce rework and miscommunication.

- Competitive Advantage: A polished, cohesive brand stands out in crowded markets.

Final Thoughts

In OEM pencil manufacturing, your brand is only as strong as its weakest execution point. From the graphite blend to the packaging design, every detail must align with your brand’s identity and values. By implementing structured systems, investing in clear communication, and prioritizing quality control, pencil brands can maintain brand consistency OEM across every product and process. In a market where trust and differentiation are hard-won, consistency is your most powerful tool.

Related Reading

- Material Sourcing Pencils: Essential Guide for OEM Buyers

- Advantages of Direct OEM Pencils for Brand Owners

- Precision OEM School Logo Pencils for Effective Branding

- OEM Pencil Pricing Guide for Manufacturers and Buyers

- Seasonal OEM Pencil Supply Strategies for On-Time Delivery

- Color Variance QC in Pencil Manufacturing Explained