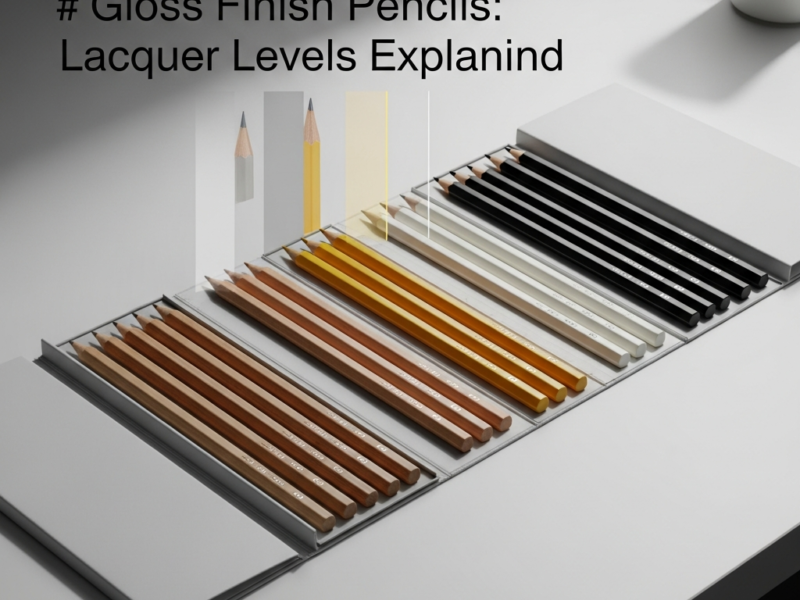

The world of premium stationery is often defined by the tactile and visual nuances that distinguish a standard writing tool from a professional-grade instrument. When we discuss gloss finish pencils, we are not merely talking about a shiny exterior, but rather a sophisticated layering process that impacts the pencil’s durability, grip, and aesthetic longevity. For artists, designers, and stationery aficionados, the level of lacquer applied to a pencil barrel is a primary indicator of quality, reflecting the care taken during the manufacturing phase to ensure the wood casing is perfectly sealed and polished. Understanding these lacquer levels is essential for anyone looking to curate a high-end collection or source products for a discerning retail market.

The Anatomy of a Gloss Finish: Beyond the Surface

To understand the complexity of gloss finish pencils, one must first look at the substrate—the wood itself. Most high-quality pencils utilize Incense Cedar or fine-grained basswood, which requires significant preparation before any lacquer can be applied. In the manufacturing world, “lacquer levels” refer to the number of times a pencil barrel is dipped or passed through a coating machine. A budget pencil might receive only one or two coats of thin paint, which often leaves the grain of the wood visible and the texture slightly rough. In contrast, premium pencils undergo a multi-stage process where several layers of lacquer are applied, dried, and sometimes even sanded between coats to achieve a mirror-like sheen. This process is not just about looks; it serves a functional purpose by preventing the wood from absorbing moisture from the air or oils from the user’s hand. This sealing process ensures that the internal graphite core remains stable and that the wood does not warp or crack over time. When a pencil features a high-gloss finish, it signifies that the manufacturer has invested in a “dipping” process that creates a thick, protective shell. This shell acts as a barrier against the rigors of daily use, ensuring that the pencil looks as good on its last inch as it did when it was first sharpened. Furthermore, the chemistry of the lacquer matters—modern manufacturers are increasingly moving toward water-based, eco-friendly lacquers that provide the same high-gloss luster without the environmental impact of traditional solvent-based chemicals. These advancements in material science allow for a depth of color and a level of clarity that was previously difficult to achieve in mass production.

The Lacquer Level Spectrum: A Manufacturing Overview

In the OEM and manufacturing sector, lacquer levels are often categorized by the number of “passes” or “dips” a pencil undergoes during the finishing stage. Each level offers a different balance of cost-efficiency and luxury feel. Below is a breakdown of how these levels typically translate to the final product quality found in gloss finish pencils across the industry.

| Lacquer Level | Number of Coats | Visual Result | Market Positioning |

|---|---|---|---|

| Level 1: Basic | 1 – 2 Coats | Slight sheen, wood grain often visible. | Budget/School Grade |

| Level 2: Standard | 3 – 5 Coats | Consistent color, smooth feel, moderate reflection. | Office/General Writing |

| Level 3: Premium | 6 – 8 Coats | High luster, deep color saturation, no visible grain. | Artistic/Professional |

| Level 4: Luxury | 9 – 12+ Coats | Piano-finish, glass-like reflection, extreme durability. | Collector/Boutique |

As the table illustrates, the jump from a standard office pencil to a luxury gloss finish pencils involves a significant increase in production time. Each additional coat requires a specific drying period, often in a temperature-controlled environment to prevent dust particles from settling on the wet surface. For a “Level 4” finish, the pencils are often passed through a burnishing machine, which uses friction to further smooth the lacquer before the final clear coat is applied. This attention to detail is what creates that iconic “piano finish” seen on some of the world’s most expensive stationery brands.

Integrating Graphite Grades: The Relationship Between Core and Coating

While the exterior finish of a pencil provides the initial appeal, the internal graphite grade is what determines its performance. According to research from industry leaders like Mont Marte, the graphite spectrum is divided into H (Hard) and B (Black/Soft) grades. When choosing gloss finish pencils, it is helpful to understand how the exterior finish complements the core. For example, a 9H pencil, which is extremely hard and light, is often used for technical drafting. Such a pencil benefits from a high-gloss finish because the hard lead requires more pressure, and the smooth lacquer provides a comfortable, low-friction surface for the fingers. On the other hand, a 9B pencil is incredibly soft and dark, ideal for expressive shading and blending. Artists using soft B-grade pencils often prefer a slightly “grippier” gloss that prevents the pencil from slipping during heavy shading sessions. The standard HB pencil, which sits in the middle of the spectrum, is the most common recipient of a gloss finish because it serves as a versatile tool for both writing and light sketching. Manufacturers often color-code their gloss finishes to match the graphite grade, using darker lacquers for B grades and lighter or metallic lacquers for H grades. This visual shorthand allows artists to quickly identify the tool they need without checking the stamped grade on the barrel. To learn more about how these grades are categorized, you can refer to the Mont Marte Pencil Grade Guide for a detailed breakdown of the H and B spectrum. Understanding the core is just as important as understanding the lacquer, as the two must work in harmony to provide a balanced drawing experience.

The Pros and Cons of High-Gloss Pencils

Choosing gloss finish pencils involves weighing the aesthetic benefits against practical considerations. While the visual appeal is undeniable, different users have different needs regarding the “hand-feel” of their tools. Here are the primary advantages and disadvantages of opting for a high-lacquer finish:

- Pro: Durability. The thick lacquer layer protects the wood from environmental factors and physical damage.

- Pro: Aesthetic Appeal. High-gloss finishes allow for vibrant colors and a professional look that stands out in a pencil case.

- Pro: Cleanliness. Glossy surfaces are easier to wipe clean of graphite dust compared to matte finishes, which can “trap” dust in their texture.

- Con: Grip Slippage. For those with sweaty hands, a very high-gloss finish can become slippery during long writing sessions.

- Con: Fingerprint Visibility. Much like a smartphone screen, a high-gloss pencil will show fingerprints and oils more readily than a matte one.

- Con: Manufacturing Cost. The multiple dipping stages required for a true gloss finish increase the retail price of the pencil.

For most professionals, the pros of gloss finish pencils far outweigh the cons. The added protection and the way the colors pop under studio lighting make them a staple in the creative industry. However, for those who prioritize a non-slip grip above all else, some manufacturers have developed “soft-touch” glosses that provide the look of a high-shine finish with a slightly rubberized texture for better control.

The Manufacturing Workflow: From Raw Slat to Glossy Masterpiece

The journey of gloss finish pencils begins in the slat department, where blocks of wood are grooved to hold the graphite cores. Once the “sandwich” of wood and graphite is glued and cut into individual hexagonal or round shapes, the finishing process begins. The first step is “sanding,” where high-speed abrasives remove any irregularities from the wood surface. This is followed by a “sealer coat,” which prevents the subsequent lacquer layers from soaking too deeply into the wood fibers. After the sealer is cured, the pencils enter the dipping station. Here, they are held by their ends and submerged into a vat of lacquer. The speed at which they are withdrawn is carefully controlled; too fast, and the lacquer will drip; too slow, and it will be uneven. After each dip, the pencils travel through a drying tunnel. For a high-end gloss finish pencils, this process may be repeated up to ten times. The final stage is the “stamping,” where the brand name and graphite grade are embossed onto the lacquer using foil or silk-screen printing. Because the surface is so smooth, the stamping must be done with precision to ensure it doesn’t flake off. Finally, a clear top-coat is often applied to protect the foil stamping and provide that final layer of depth. For more insights into the history and technical evolution of this process, the resources at Pencils.com – The Pencil Making Process offer a great historical perspective on how these techniques have evolved from manual dipping to high-tech automation.

Material Science: What Is in the Lacquer?

The chemical composition of the coating on gloss finish pencils has evolved significantly over the last few decades. Historically, nitrocellulose lacquers were the industry standard because they dried quickly and produced a very hard, shiny surface. However, these lacquers contain high levels of Volatile Organic Compounds (VOCs), which pose environmental and health risks during the manufacturing process. Today, the shift is toward water-borne acrylic lacquers. These modern coatings are engineered to provide the same refractive index as traditional lacquers—meaning they are just as shiny—while being much safer for factory workers and the end-user. Some premium brands also incorporate UV-curable resins into their finishing lines. These resins harden almost instantly when exposed to ultraviolet light, allowing for a much faster production cycle without sacrificing the thickness of the gloss finish pencils. Additionally, the pigments used in these lacquers must be finely milled to ensure that the color is perfectly opaque. If the pigment particles are too large, they can create microscopic bumps that ruin the “glass” effect of the finish. In the high-end market, some lacquers even include pearlescent or metallic flakes, which require even more careful application to ensure the flakes lay flat and reflect light evenly across the curved surface of the pencil barrel.

The Role of Gloss in Branding and Consumer Psychology

In the retail environment, gloss finish pencils often command a higher price point because they subconsciously signal quality to the consumer. The way a glossy surface reflects light draws the eye more effectively than a matte surface, making these pencils stand out on a crowded shelf. From a psychological standpoint, a smooth, polished object is often perceived as being more “finished” or “refined.” This is why many luxury brands choose a high-gloss black or deep navy for their flagship products. It mimics the look of high-end automotive finishes or luxury fountain pens. For an OEM brand, choosing the right lacquer level is a strategic decision. If the target audience is students, a Level 1 or 2 finish is sufficient and keeps costs low. However, if the target is the professional art market, a Level 3 or 4 finish is almost mandatory to meet consumer expectations. The finish is the first thing a customer feels when they pick up the pencil, and in a world where tactile experiences are increasingly rare, the “hand-feel” of a perfectly lacquered gloss finish pencils can be a major selling point. It conveys a sense of weight and substance that a cheaply finished pencil simply cannot replicate.

Specifications and Quality Control in Gloss Finishing

To maintain consistency, manufacturers use specific metrics to measure the quality of gloss finish pencils. One of the most common tools is a gloss meter, which measures the amount of light reflected from the surface at a specific angle (usually 60 degrees). A high-gloss pencil might score above 80 Gloss Units (GU), while a semi-gloss would fall between 30 and 7

Related Reading

- Prevent Color Migration in Pencil Coating Processes

- Preventing Paint Peeling in Mechanical Pencil QC

- Essential Guide to Varnish Pencil Coating Types

- Why Multi-Coating Pencils Improves Durability and Precision

- How to Prevent Pencil Scratches in Manufacturing

- Understanding Gloss vs Matte Pencils for Artists

- The Impact of Wax on Pencil Smoothness

- Pencil Smoothness Test: How to Evaluate Quality Purchases