Unlike standard writing pencils, artist-grade pencils demand exceptional pigment quality, consistency, blendability, and durability. These requirements push factories to develop dedicated production lines, material sourcing strategies, and proprietary techniques. In this article, we’ll explore why specialized core production is essential in artist pencil factories and how it influences the final product’s performance, sustainability, and value.

The Core Difference: Artist Pencils vs. Standard Pencils

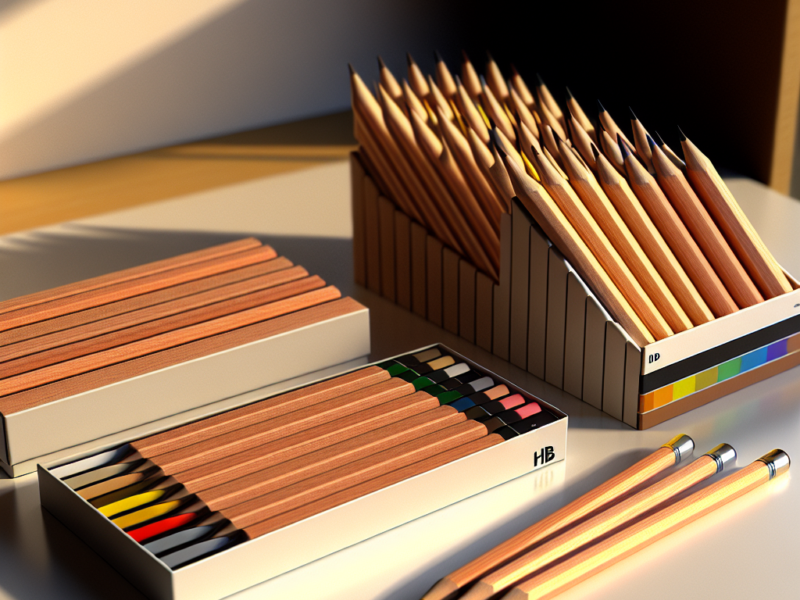

At a glance, all pencils may look similar — a wooden casing with a pigmented center. But the similarities stop there. The core of an artist pencil is engineered for a completely different purpose than that of a general writing pencil. While a typical HB pencil is optimized for durability and legibility, an artist pencil must deliver smooth laydown, rich pigmentation, and control across various paper types.

| Feature | Artist Pencil | Standard Pencil |

|---|---|---|

| Core Composition | High pigment content, fine clay or wax binders | Graphite with clay binder |

| Color Range | Extensive (dozens to hundreds of shades) | Typically grayscale (HB to 9B) |

| Blendability | Excellent for layering and shading | Limited — designed for writing |

| Lightfastness | Often rated for archival quality | Not rated |

| Application | Fine art, illustration, professional design | Writing, drafting, general use |

This fundamental difference in purpose requires a completely different approach to core production.

Why Core Production Is the Heart of an Artist Pencil Factory

The core is where the magic happens. In an artist pencil factory, developing the perfect core formula is a blend of chemistry, engineering, and artistry. The process involves selecting high-quality pigments, precise binder ratios, and controlled extrusion methods to ensure consistency and performance.

Here’s why specialized core production is so critical:

- Color Accuracy: Artists rely on pencils that match expected hues. This demands consistent pigment dispersion and minimal batch variation.

- Blendability and Texture: The tactile feel of the pencil — whether waxy, creamy, or dry — depends on core formulation. This affects how pencils layer, smudge, or resist blending.

- Durability and Sharpening: A brittle or overly soft core can break during sharpening or use. Balancing softness with structural integrity is key.

- Lightfastness: High-end artist pencils often use pigments rated for UV resistance to ensure artwork doesn’t fade over time.

These performance criteria require more than just high-quality materials — they demand a controlled production environment and expert formulation knowledge.

Material Inputs: Pigments, Binders, and Additives

At the core of core production lies a deep understanding of materials science. The three primary ingredients in an artist pencil core are:

- Pigments: These are finely ground colorants, often sourced from mineral, synthetic, or organic origins. Unlike dyes, pigments are insoluble and provide opacity and vibrancy. As detailed in this pigment industry overview, the focus today is on sustainable, high-performance pigments that minimize environmental impact while maximizing color fidelity.

- Binders: Materials like waxes (paraffin, beeswax), oils, or clays help hold the pigment together and determine the pencil’s texture. Wax-based cores are common in colored pencils, while oil-based cores offer smoother, more blendable results for professional use.

- Additives: Stabilizers, lubricants, and fillers are introduced to improve sharpening, prevent breakage, or enhance glide. These are carefully balanced to avoid compromising pigment concentration.

The interplay of these materials is what gives each pencil brand its signature feel and performance. Any deviation in raw material quality or processing can result in noticeable differences in the final product.

Precision Manufacturing: The Core Extrusion Process

Once the core mixture is formulated, it undergoes extrusion — a process where the soft paste is forced through a die to form uniform rods. These rods are then dried, cut, and cured before being encased in wood. In artist pencil factories, this step is executed with extreme care, as even minor inconsistencies in diameter or density can affect the pencil’s usability.

High-end factories often use temperature-controlled environments and automated monitoring systems to ensure consistency. Some even incorporate laser measurement tools to detect imperfections or air pockets that could weaken the core.

Why Color Fidelity and Lightfastness Matter to Professionals

One of the defining features of professional-grade art materials is their color fidelity — the ability to reproduce consistent, vibrant shades across different batches. In the context of pencils, this is only achievable through rigorous pigment selection and controlled processing.

The manufacture of oil colors offers a relevant comparison. Just like in oil paint production, artist pencil factories must ensure that pigments are not only vibrant but also stable and archival. Lightfastness ratings (commonly tested using ASTM standards) help artists choose materials that won’t fade with time or exposure to sunlight.

This is particularly important for professional illustrators, gallery artists, and conservators who require their work to last for decades — if not centuries.

Balancing Range and Resourcefulness

Interestingly, while manufacturers offer extensive color ranges (sometimes 120+ shades), not all artists use them all. A discussion among professional miniature painters revealed that many rely on a limited palette, opting for color mixing and layering techniques over sheer quantity.

This insight speaks to a broader principle: quality over quantity. For manufacturers, this means focusing on the performance of each core, rather than flooding the market with redundant shades. For artists, it reinforces the value of mastering technique — a high-quality pencil with dependable behavior is far more useful than a vast set of inferior tools.

Industrial Innovation Meets Artistic Expression

Artist pencil factories are a prime example of how industrial precision meets creative potential. Much like installation artists who repurpose industrial materials for expressive works — as explored in this installation art study guide — pencil manufacturers harness industrial processes to empower artistic expression.

From automated pigment blending systems to eco-friendly binder alternatives, innovation in factory settings directly translates to better tools for creatives. The rise of sustainable pigments and recyclable packaging is also shaping how artist pencil factories operate, aligning with global trends in green manufacturing.

Conclusion: The Art of Manufacturing Art Tools

Behind every vibrant stroke of a colored pencil lies a world of science, engineering, and craftsmanship. Specialized core production is not a luxury — it’s a necessity for any artist pencil factory aiming to serve professional creatives. From pigment sourcing to extrusion precision, every step is optimized to meet the high standards of the art community.

As artists continue to push the boundaries of expression, manufacturers must match that ambition with technical excellence. Whether you’re a seasoned illustrator or a supplier sourcing OEM pencils, understanding the importance of specialized core production is key to appreciating — and delivering — true artistic quality.

Related Reading

- Pencil Sharpening Test Method Used in Factories

- Metallic Pencils OEM Production Process Explained

- Why Carpenter Pencils Need a Strong Core

- How Graphite Density Impacts Pencil Performance

- Inside Durzerd Pencils Manufacturing for Graphite Consistency

- Graphite Extrusion Process and Core Mixing Explained

- Pencil Production Line Explanation and Step-by-Step Process