Private Label Pencils Guide for South America Importers

In recent years, the demand for private label pencils has surged across South America. From educational suppliers in Brazil and Argentina to promotional product distributors in Chile and Colombia, importers are increasingly seeking custom pencil solutions that reflect their brand identity. Whether you’re sourcing for schools, offices, or retail, understanding the full scope of OEM pencil production is key to building a successful import strategy.

This guide walks South American importers through the essential steps of sourcing logo pencils bulk, including manufacturing options, compliance standards, and smart supply chain practices. If you’re looking to partner with a manufacturer for private label pencils, this article will help you make informed, confident decisions.

Why Private Label Pencils Are Gaining Popularity

Private label products allow companies to build brand equity without owning a factory. In the case of pencils, this means you can offer high-quality, customized writing instruments under your own brand — whether you’re a stationery retailer, school supplier, or promotional distributor.

For South American markets, private label pencils offer several advantages:

- Brand Control: Customize design, packaging, and messaging.

- Cost Efficiency: Leverage economies of scale with bulk production.

- Market Differentiation: Stand out with unique features like eco-friendly materials or specialty finishes.

As education budgets grow and businesses seek sustainable promotional products, the demand for custom pencils continues to rise.

Understanding OEM Pencil Manufacturing

OEM (Original Equipment Manufacturer) production is the backbone of the private label pencil industry. As an importer, you collaborate with a factory that produces pencils to your specifications — including shape, color, branding, and packaging.

Here’s a simplified breakdown of how OEM pencil manufacturing usually works:

| Stage | Description |

|---|---|

| Design Brief | You provide specifications: pencil type, logo placement, materials, packaging style. |

| Prototype | Factory creates samples for your approval before mass production. |

| Production | Once approved, bulk manufacturing begins, typically in batches of 10,000 units or more. |

| Shipping & Compliance | Products are labeled, packed, and shipped according to import regulations. |

Working with a reliable OEM partner ensures quality control and consistency across batches — critical for building consumer trust.

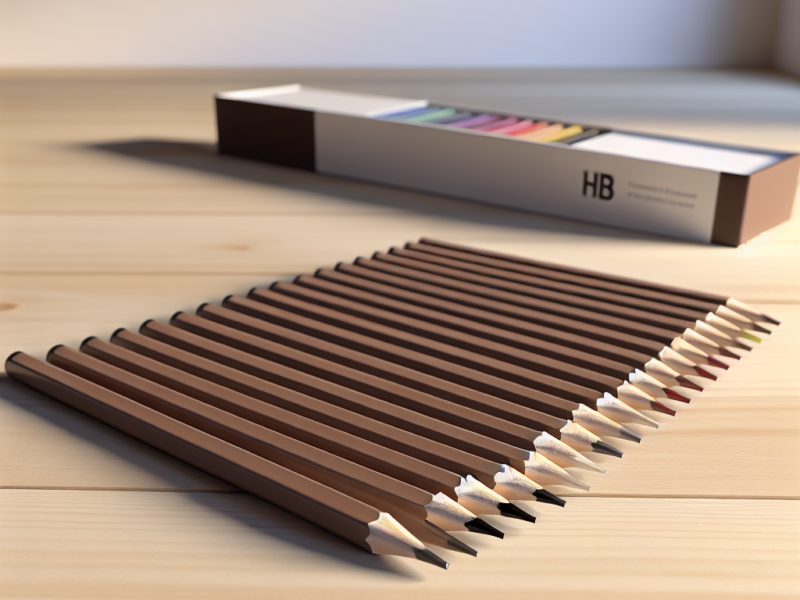

Choosing the Right Pencil Materials

Material selection plays a big role in product performance and market appeal. As a South American importer, you’ll want to balance cost, sustainability, and user experience.

Here are the most common pencil materials used in private label production:

- Cedar Wood: Premium feel, smooth sharpening, often used in high-end pencils.

- Basswood or Poplar: Cost-effective alternatives with decent performance for school and office use.

- Recycled Paper or Plastic: Eco-friendly options gaining popularity in sustainable product lines.

For graphite cores, standard HB is the most versatile, while 2B, 4B, and other grades are often used for art or specialty applications. Colored pencils require wax- or oil-based cores, which impact smoothness and pigment intensity.

Customization Options for Logo Pencils in Bulk

Customization is where your brand comes to life. Whether you’re promoting a school, business, or campaign, the following features can be personalized in bulk:

- Barrel color and finish (matte, glossy, natural wood)

- Logo printing (screen print, foil stamp, laser engraving)

- Eraser color and ferrule style (metallic, painted, or raw)

- Packaging (bulk boxes, blister packs, branded sleeves)

For promotional use, screen printing is the most common method due to its affordability and speed. However, laser engraving offers a more premium, long-lasting look, ideal for corporate gifting or retail lines.

Minimum Order Quantities (MOQs) and Lead Times

Most OEM pencil factories require a minimum order quantity (MOQ) to justify setup and tooling costs. Here’s a general guideline:

- Standard graphite pencils: MOQ 10,000–20,000 units

- Colored pencils: MOQ 5,000–10,000 sets

- Specialty finishes or eco-materials: MOQ 25,000+ units

Lead times vary by complexity, but typically range from 30–60 days after sample approval. Be sure to factor in shipping time to South America, which can add 2–4 weeks depending on the port and customs clearance.

Country of Origin Marking and Compliance

When importing private label pencils, proper labeling is not just good practice — it’s a legal requirement in many countries. For example, U.S. regulations mandate that all imported products visibly display the country of origin in English.

While this guide focuses on South America, similar principles apply. Ensuring that your products are marked with “Made in China,” “Made in Brazil,” or the appropriate designation protects your business from customs delays and builds consumer trust.

For reference, the U.S. Customs and Border Protection offers a detailed publication on this topic: Marking of Country of Origin on U.S. Imports.

Even if you’re not importing into the U.S., aligning with these international best practices can help your brand maintain credibility and avoid legal complications in future market expansions.

Shipping, Import Duties, and Logistics Tips

Shipping bulk pencils to South America involves several key considerations:

- Freight Method: Sea freight is most cost-effective for large volumes; air freight is faster but expensive.

- HS Codes: Pencils typically fall under HS Code 9609.10, which affects duties and tariffs.

- Customs Clearance: Work with a local broker to ensure smooth processing and avoid delays.

Be proactive about documentation — including invoices, packing lists, and certificates of origin. Many South American countries offer preferential trade agreements that can reduce import costs if your paperwork is in order.

How to Vet a Private Label Pencil Manufacturer

Choosing the right manufacturing partner is critical. Look for factories with:

- ISO or FSC certifications (for quality and sustainability)

- Experience with international clients and export logistics

- Transparent communication and willingness to provide samples

- Flexible MOQs and scalable production capacity

Ask for references or case studies, and don’t hesitate to request a video tour of their production facility. A trustworthy partner will be proud to show their process.

Common Pitfalls to Avoid

Importing private label pencils can be profitable — but only if you avoid these common mistakes:

- Skipping samples: Always approve a prototype before mass production.

- Underestimating lead times: Build in buffer time for production and shipping delays.

- Ignoring compliance: Improper labeling or documentation can result in costly fines or rejections.

It’s also wise to diversify your supplier base or establish backup vendors in case of geopolitical disruptions or raw material shortages.

Conclusion: Building a Resilient Pencil Import Strategy

Private label pencils offer South American importers a powerful opportunity to grow their brand and meet market demand. By understanding OEM manufacturing, compliance requirements, and customization options, you can source logo pencils bulk with confidence and consistency.

Whether you’re launching a new product line or scaling an existing one, success starts with informed decisions. For further reading on international trade compliance and labeling, explore the U.S. CBP’s official guidelines.

With the right strategy and partners, your private label pencil business can sharpen its competitive edge — one pencil at a time.